Pipeline Casing Protection

THE PROBLEM

Underground pipelines are required to have cathodic protection to protect them from corrosion. When these pipelines run under roadways, railway lines, etc. they have historically been required to have protective metal casings. Over time, there may be movement of the product carrying the inner pipeline (“carrier pipe”) and/or the casing that brings the carrier and casing into contact. This results in a “metallic short” that causes the cathodic protection current to pass through the casing.

Pipe Casing Protection

For more information,

The regulatory requirement for pipeline casings with metallic shorts is for pipeline owners to do one of the following:

- Excavate the buried pipeline, fix the short and resume operations ($$$$)

- Fill the pipe casing with wax ($$)

- Use a Vapor Corrosion Inhibiting gel ($)

In addition to shorted casings, buried pipe and casing assemblies typically have trapped moisture, oxygen, and other contaminants that can accelerate the corrosion process inside the casings. These contaminants may also enter through cracks or gaps in the end seals causing corrosion of the carrier pipe and the casing. Over time, penetrations in the casing, or end seals, can also contribute to the ingress of moisture and contaminants. Accumulated moisture can puddle and stagnate, accelerating corrosion.

Current guidelines by NACE (National Association of Corrosion Engineers), SP0200-2014 offer the option of using Vapor Corrosion Inhibitors (VCIs) as a corrosion mitigation technique.

The Solution

Zerust has developed a unique blend of corrosion inhibitors and gels that is injected into the annular pipe casing space. The Zerust corrosion inhibitors protect the carrier pipeline both in direct contact, using Soluble Corrosion Inhibitors, and also through Vapor Corro-sion Inhibitors that protect the entire annulus vapor space.

How the pipe casing solution works

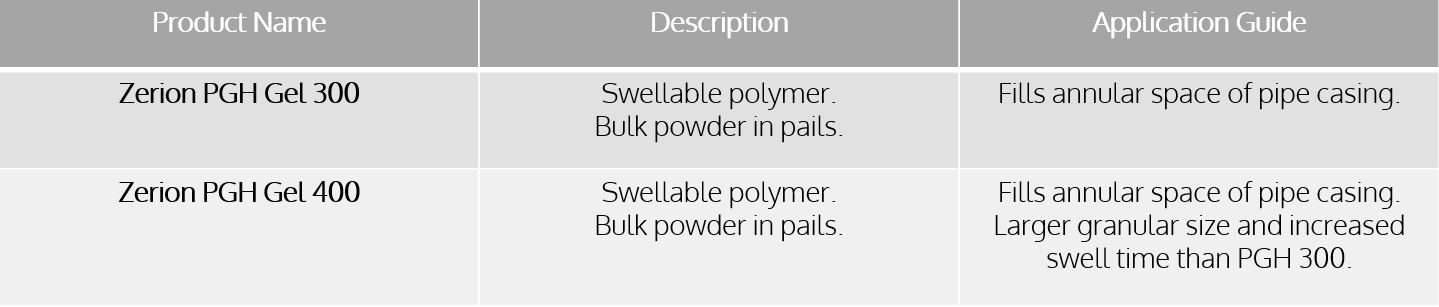

High Viscosity Gel Application

WHEN: For pipelines with a metallic short (i.e., casing in contact with the carrier pipe) or pipelines where a static fill anti-corrosion solution is needed. This also meets PHMSA requirements for a protection system that remains in place.

HOW: The gel system is installed as a low viscosity slurry which sets up as a high viscosity gel. The VCI molecules volatize from the gel to protect the vapor spaces in the annulus. The SCI in the product neutralizes contaminants on contact. The gel system has advantages over the other two applications in that, as the gel sets up, it can bridge small penetrations and reduce the possibility of the solution leaking out of the casing. Conversely, it helps slow down the ingress of contaminants from the outside.

Powder Application

WHEN: For pipelines without a metallic short, but for which providing internal corrosion protection is a good operating procedure, Zerust recommends the use of its dry powder inhibitor. If there is minimal water ingress (i.e., end seal integrity is maintained) the system will protect the carrier pipe from corrosion.

HOW: A simple blower system is used to blow Zerust’s proven blend of Zerion powder inhibitors down into the pipe casing through the casing vent pipes. The Zerion powder is blown down the entire length of the annulus and settles on the bottom of the casing pipe. SCIs neutralize contaminants in the bottom while VCI volatizes to protect the metal surfaces in the vapor space. The entire annular space of the cased pipeline is protected.

Slurry Application

WHEN: For long lengths of pipe with varying elevations, bends, and other geometric/dimensional parameters where a powder or gel is not feasible.

HOW: Zerust’s unique Zerion FVS is first mixed with water. Gravity or a low-pressure pump is then used to inject the inhibitor slurry through the casing vent pipe into the annular space. The SCI in the product neutralizes contaminants on contact. The VCI molecules are released and equalize in the remaining vapor space, protecting both the exterior of the carrier pipe and the inside of the casing. The entire annulus space of the cased pipeline is protected. The liquid injection is especially beneficial for longer casings if the integrity of the casing and end seals can be proven.