Storage Tank Roof Protection

The Problem

• Destroyed internal surfaces and support structures of storage tank roofs above the product layer from oils that contain sulphur emitting corrosive vapors.

• Unsafe operating conditions and environmental problems caused by aggressive pitting and crevice corrosion that create holes in the tank tops.

• Internal tank coatings are ineffective in preventing dangerous pitting and crevice corrosion, especially in the spaces between the roof and support structures.

• Stoppage of tank operations and necessitating periodic roof replacements impact petrochemical facilities causing capital losses and increased intangible costs.

The Solution

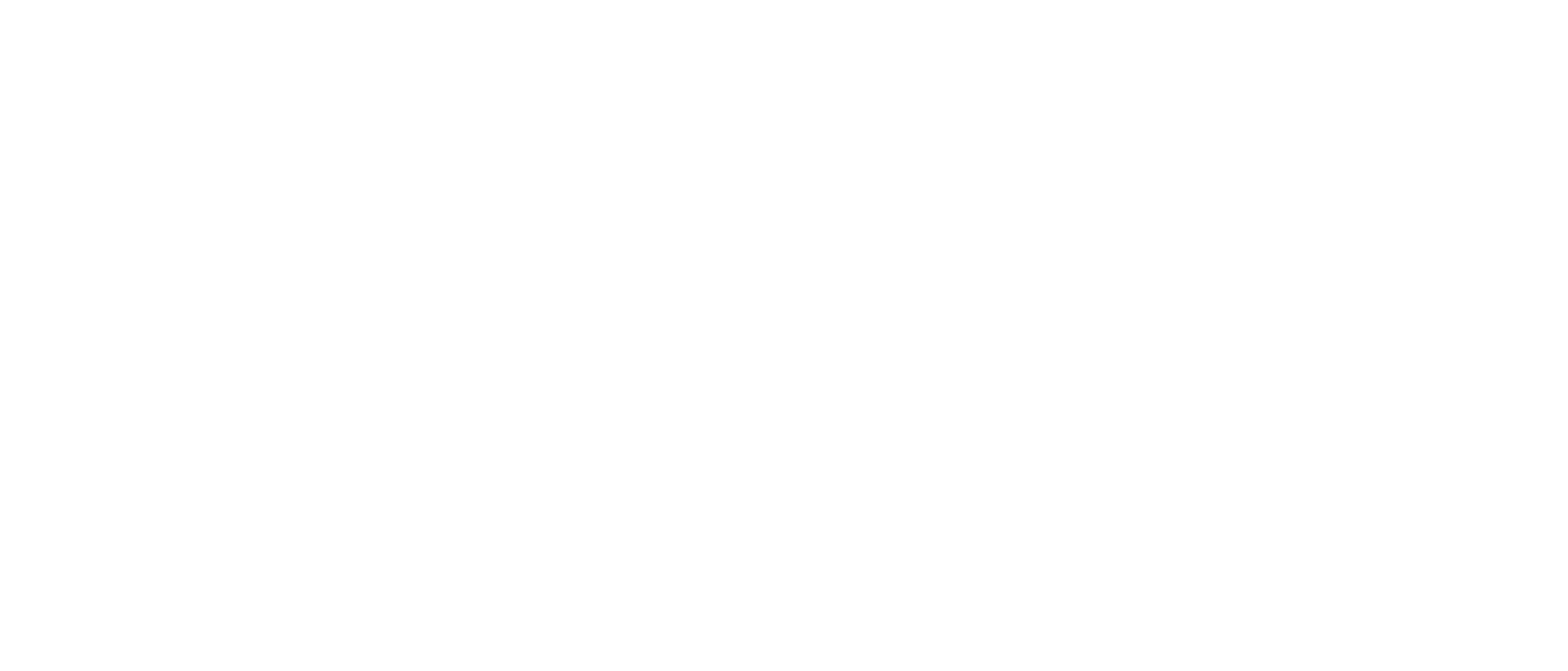

- Zerust ReCAST-R is the solution for this problem. The Zerust ReCAST-R system can be installed & deployed in aggressive operational internally corrosion environments.

- Dispensers attached to the tank roof deliver VCIs automatically into the tank vapor space forming a protective barrier layer.

- The barrier layer isolates the corrosive environment from the metallic surfaces that contact the vapor space.

- Proven to be effective in the unique and unpredictable internal environment resulting from vast variations in the:

- Properties of the stored product

- Ambient temperature ranges

- Temperature of the stored product

- Method of construction & design of the tank

- Tank operational parameters

- Compatible with many additional systems that might be in place including: scrubbers, nitrogen blankets and vent systems.

Product Use

- All metallic surfaces contacting vapor space within the tank roof can be protected.

- Side wall sections of the tank above the level of the stored product and support structures.

- Both new and old tanks. Even if corrosion has started, the solution, once deployed, inhibits further corrosion.

- In operational tanks. The inhibitor does not contaminate the stored crude oil products.

Solution Effectiveness

Operating Environment Inside the ASTs

ReCAST-R Benefits

- Extend Tank Service Life.

- Protect Exposed Vapor Space Surfaces from Corrosion.

- Reduce Maintenance Costs.

- Reduce Stored Product Losses & Contamination. Eliminate the Need to Replace Carbon.

- Steel with Expensive Alternatives.

- Dispense Corrosion Protection Automatically. Reduce Environmental Contamination.

- Prevent Acid Gas Corrosion in Vapor.

- Spaces of Aboveground Storage Tanks.

Duration of Protection

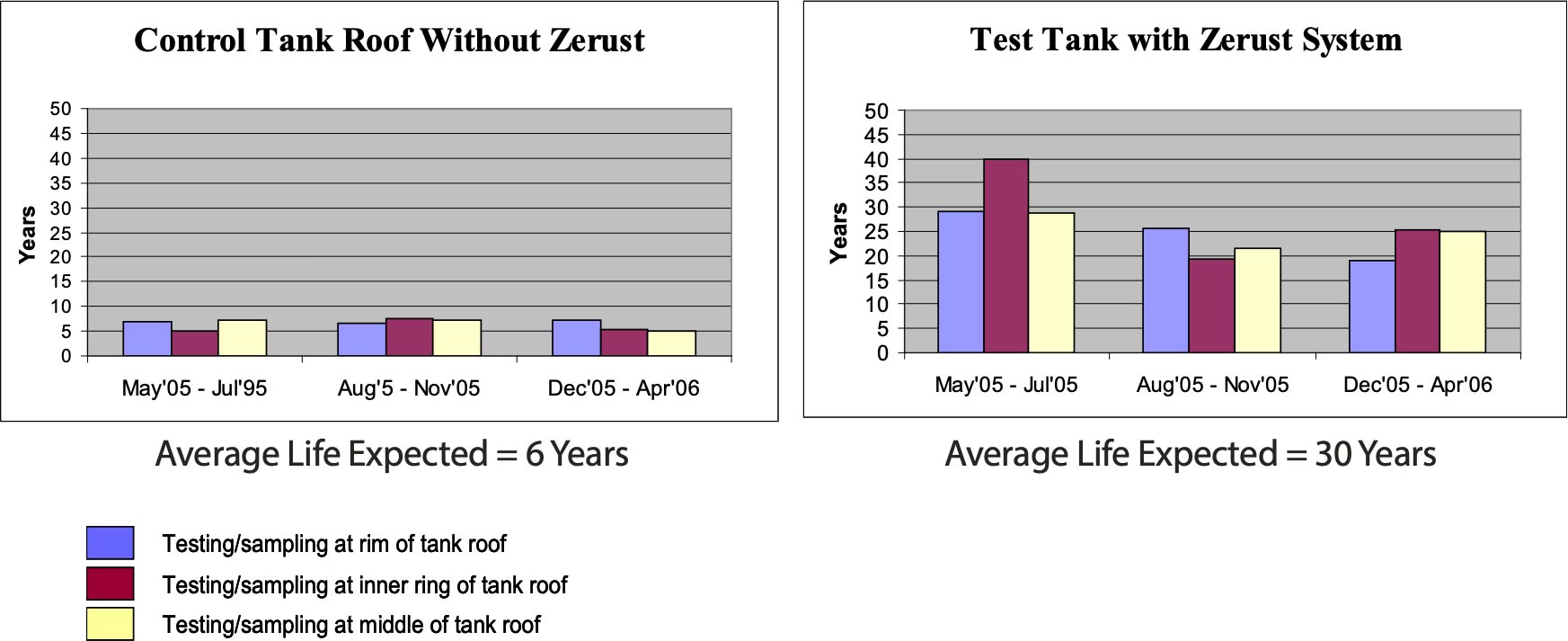

- The Zerust® solution dramatically reduces the rate of corrosion by 4 to 5 times.

- The expected life of the roof is increased from about 5-7 years to more than 25 years.

Product Properties

- Steel Cylinder Dispenser VCI liquid

Safety and Handling

- Avoid contact with eyes and skin through use of safety glasses and gloves.

- Use a full face respirator with organic cartridges, protective clothing and gloves

- See MSDS for more information.